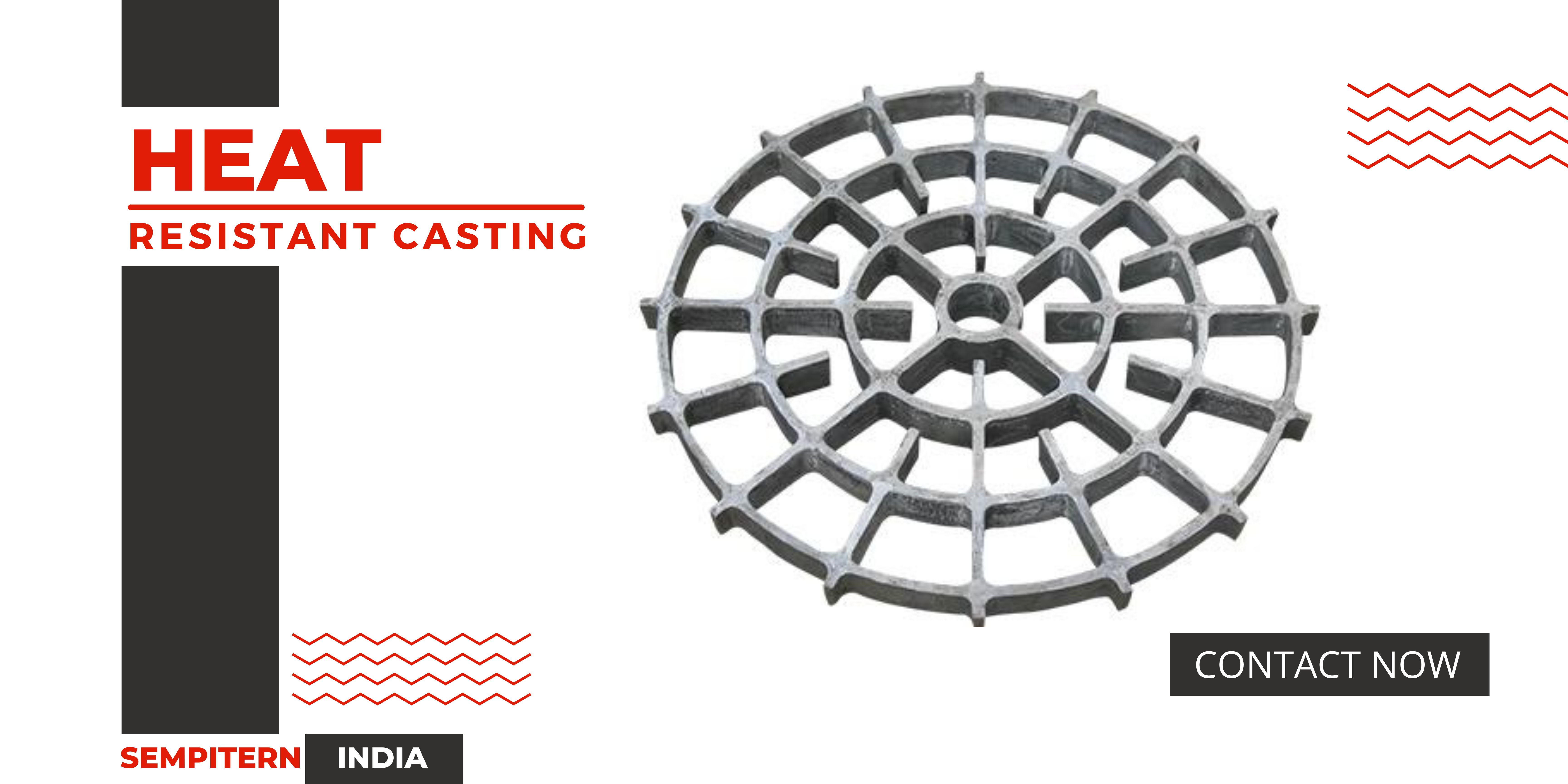

Heat Resistant Casting

The offered Heat Resistant Casting is made available by us for use in the various commercial and industrial applications. They are those compositions that contain at least 12% chromium which are capable of performing satisfactorily when used at temperatures above 1200 F. The heat-resistant compositions are higher in alloy content than the corrosion-resistant types. The castings are used when cast irons cannot deliver enough strength or shock resistance. The casting is the product formed by pouring liquid steel into a mould cavity. The offered Heat Resistant Casting is very efficient and necessary for use in the various industrial processes and applications.

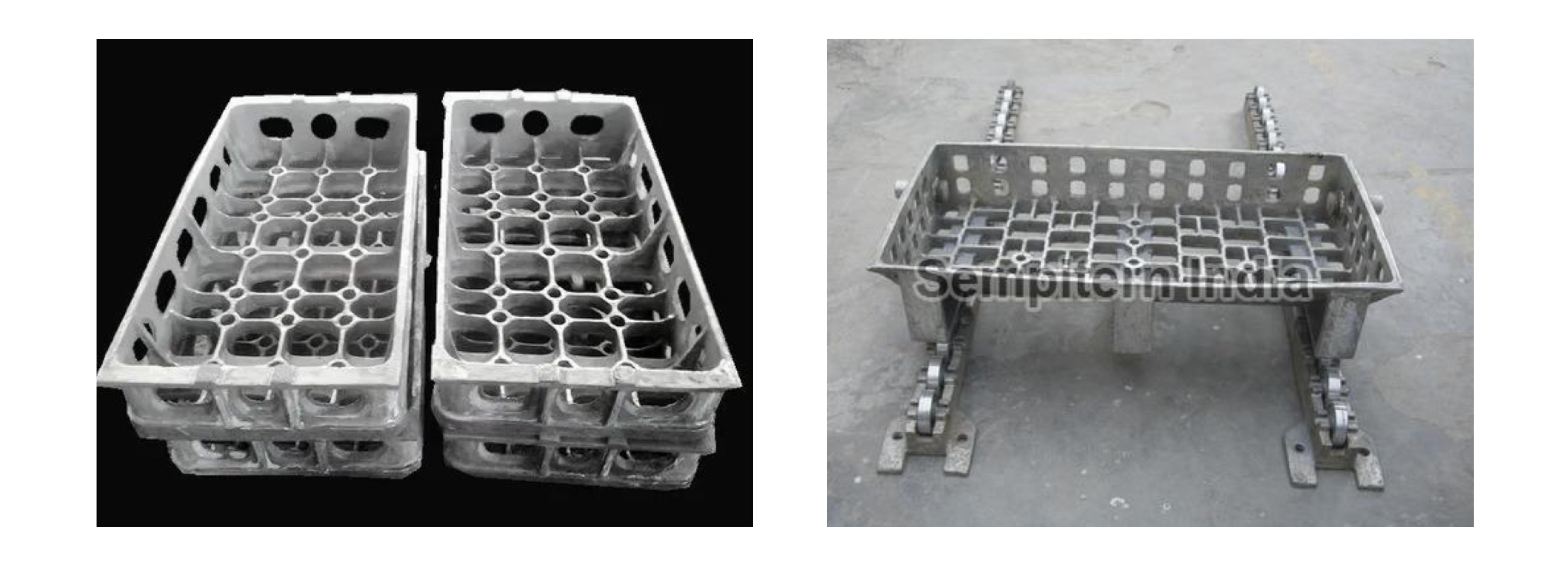

Heat Resistant Fixtures for Gas Carburizing Fixtures

Heat Resistant Base Trays, Rails & Rollers for Normalizing Furnace

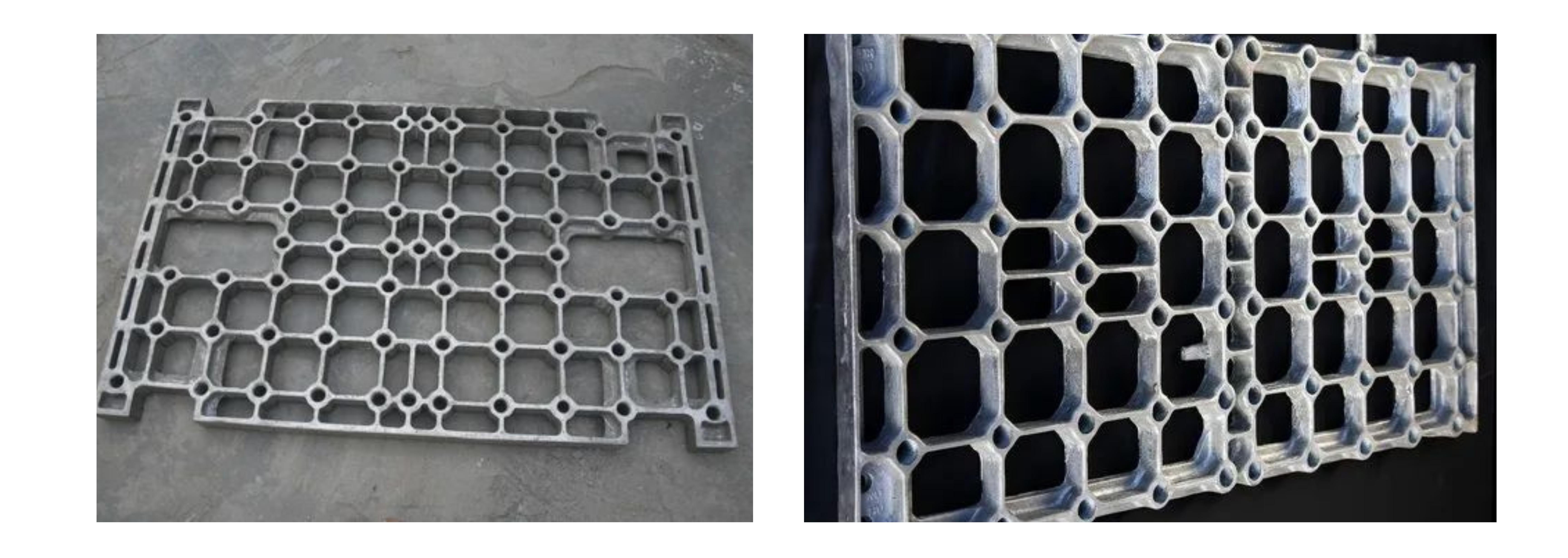

Heat Resistant Base Grids for Sealed Quench Furnaces

Corrosion resistant Castings for Food & Biotech, Flow Control Valves etc.